Founded as Motor and Machinery Castings in 1923 by Joseph H. Barron, the company has flourished through three industrial revolutions. What began as a Detroit iron sand foundry producing castings up to 60 tons, has evolved into a global manufacturer of precision machined castings and assemblies for aerospace, defense, space, automotive, energy technology and other commercial industries.

Barron Industries can be traced to casting components for Henry Ford out of Detroit in the ’20s. Born in the second industrial revolution with the assembly line, the manufacturer witnessed and employed the third industrial revolution with automation, and now is an active player in Industry 4.0. Throughout its history, the company has striven to constantly innovate and meet the needs of its customers, employees and community. Ahead of its time, Barron implemented Industry 4.0 in 2003 when it installed a cloud-based ERP system that fully integrated and automated all business functions. As in our first century, innovation will continue to be Barron’s focus in our next hundred years.

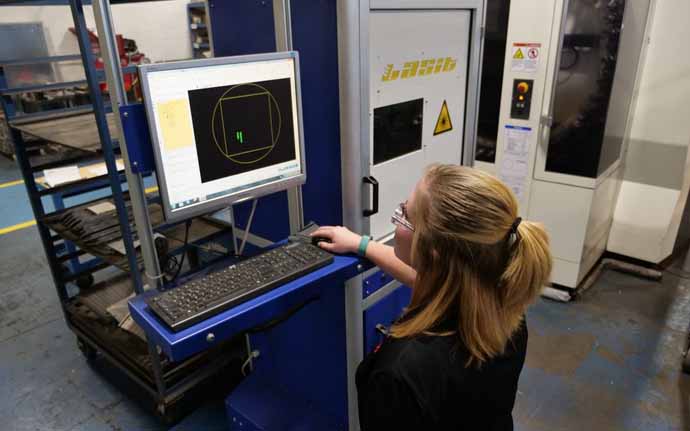

Barron’s turnkey manufacturing capabilities include design for manufacturing, rapid prototyping, CNC machining, non-destructive testing, plating, painting, assembly, laser etching, and custom packaging. More than 200 ferrous and non-ferrous alloys poured include Class II armor, stainless steels, tool steels, aluminum, cobalt, and nickel-based alloys. We are AS9100D and NADCAP Accredited for digital radiography, penetrant testing and welding. Barron’s numerous quality certifications ensure product integrity in everything we do.

NADCAP – Nondestructive Testing • AS 9100 • ISO 9001 • ITAR Registered • SAM Registered • Certified Small Business • Cage code 7L135 • Primary NAICS: 331512, 331524, 331529, 332710

Cage code 7L135 – Primary NAICS: 331512, 331524, 331524, 331529, 332710

Other Memberships and Industry Participation:

Investment Casting Institute (ICI) • American Foundry Society (AFS) • Automation Alley • National Defense Industry Association (NDIA) • Association of United States Army (AUSA) • Society of Manufacturing Engineers (SME) • U.S. Small Business Association (SBA)

To provide our customers world-class metal products and exceptional customer service that make Barron Industries their supplier of choice.

Earning industry certifications and awards, and collecting countless success stories, we’ve served many of our customers not just for years, but for decades. All engineered metal components are manufactured under our AS9100 Certified quality system which includes NADCAP Certification for our penetrant testing, digital radiography and welding processes. We are also in the process of acquiring NADCAP, the aerospace industry’s quality certification, for our other in-house processes. Our ability to perform all testing, inspection and certification in-house reduces costs and lead times by an average of 30 percent. In addition, we’ve won industry awards for converting costly multi-piece fabrications into single-piece investment castings for less than half of the original cost.

By working with our customers’ design teams, we forge relationships, deliver custom solutions and help turn concepts into superior metal products. From the beginning, we’re involved in engineering for manufacturability which helps avoid problems and reduce cost, and because we’re vertically integrated, we control the whole process in-house. Our engineers are ready to assist our customers in selecting the alloy best suited to the rigors of your specific application. When desired, Barron Industries also provides design suggestions and feedback resulting in castings with improved manufacturability. Our customers come to Barron for our superb casting quality and on-time delivery and stay with us because of our metallurgical and casting design expertise.

We are driven to unleash our experience to help our customers create value. By delivering timely solutions, by providing turnkey processes, never compromising quality, and doing so with a global market mindset. At Barron Industries, we engineer efficient processes that ensure high quality products, timely delivery and lasting value. Our capabilities are comprehensive, from design and development to production, as well as shipping and delivery anywhere in the world. And, because we compete on a global basis, we maintain strategic alliances with manufacturing companies around the world.

Our promise is to utilize our experience, capabilities and passion to provide the very best engineered solutions for our customers around the globe. We deliver turnkey results that increase quality, increase bottom lines and decrease time to market. Our relentless pursuit is to deliver superior casting solutions.

Speak to one of our experts today to learn more about our custom casting solutions.