Rapid prototyping is best utilized when the client requires only a few parts and anticipates future design changes. In just a few hours, we can convert your CAD data into a prototype pattern for use in your fit, form or function testing.

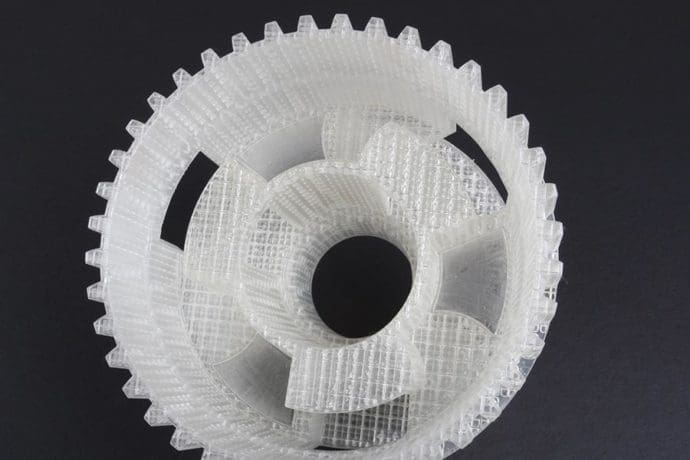

Barron Industries has been producing RP castings from 3D printing technology since 1994. Today we can produce investment castings from most 3D printed materials used in advanced SLA, FDM and SLS equipment. This process produces high quality and complex precision casting patterns in a matter of hours.

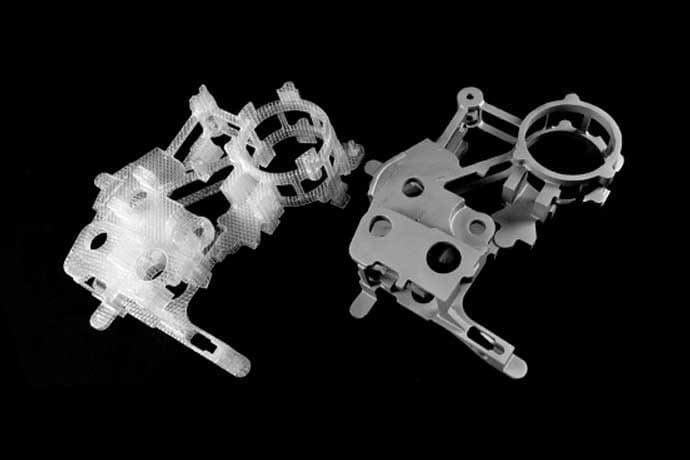

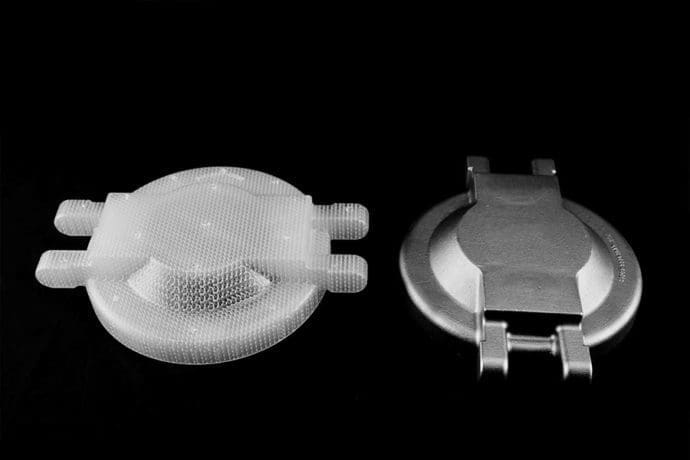

The Barron Industries Rapid Prototyping process uses layered modeling techniques to create a precise model or pattern of the proposed investment casting component in resin or wax. The model can then be used as-is or cast to desired specifications in a wide variety of alloys without the expense of additional tooling.

Barron is frequently asked to participate in up front design with its customers to ensure manufacturability and the lowest cost design while maintaining critical machining tolerances.

Barron uses Plex® manufacturing Enterprise Resource Planning (ERP) software to eliminate errors and speed up the rapid prototyping process. Our expert engineers monitor the process and make informed decisions based on real-time data. To ensure the accuracy of every prototype casting, they use the following four-step process:

Convert the math data or three-dimensional model (3D) into a solid model casting file and run solidification modeling.

Build and cure the rapid prototype pattern, via a 3D printer (Projet) or Stereolithography (SLA) technology.

Inspect the rapid prototype pattern to ensure it meets both surface finish and dimensional specifications.

Manufacture and deliver the functional investment casting rapid prototype for validation.

Speak to one of our experts today to learn more about our custom casting solutions.