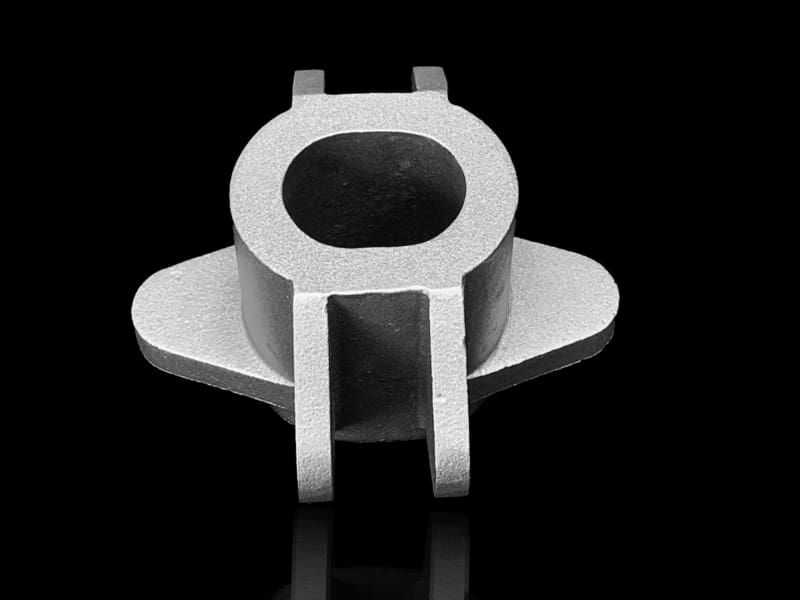

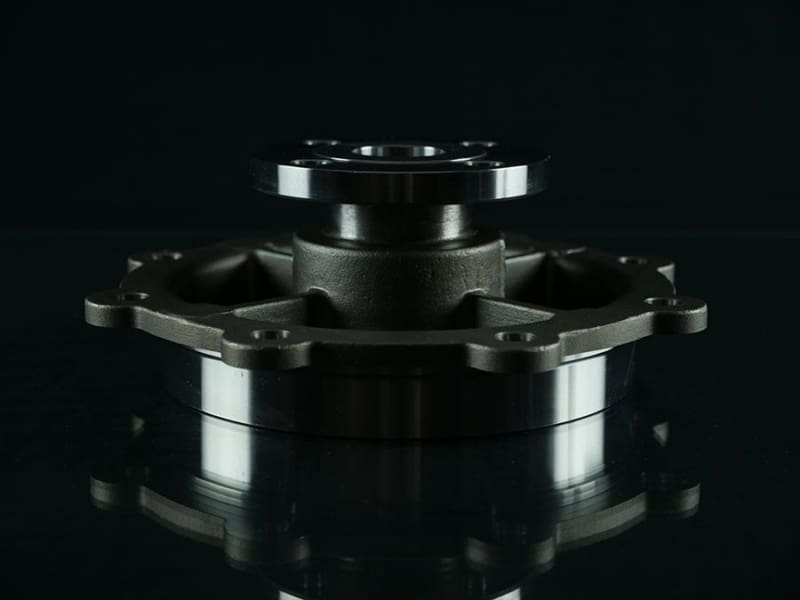

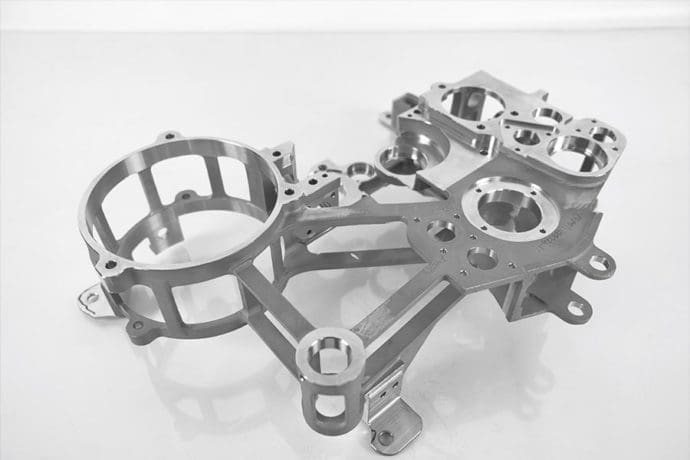

High Strength. Light Weight.

In the metal casting foundry business since 1923, we are experts in melting and pouring both ferrous and non-ferrous materials. In addition to aluminum, alloy steels and stainless steel, Barron pours all alloys that can be air melted or inert atmosphere melted including 600 series Inconel alloys as well as Hastelloy X and C.

We specialize in high-strength stainless steel, aluminum and armor alloys. Customers turn to Barron Industries to meet premium mechanical properties through a combination of strict process controls and secondary thermal treatment parameters in alloys such as 17-4 PH Stainless Steel and A357-T6 Aluminum. Barron pours more than 200 different ferrous and non-ferrous alloys.

Have any Questions?

Please feel free to contact us. We will get back to you within 1-2 business days. Or just call us now.