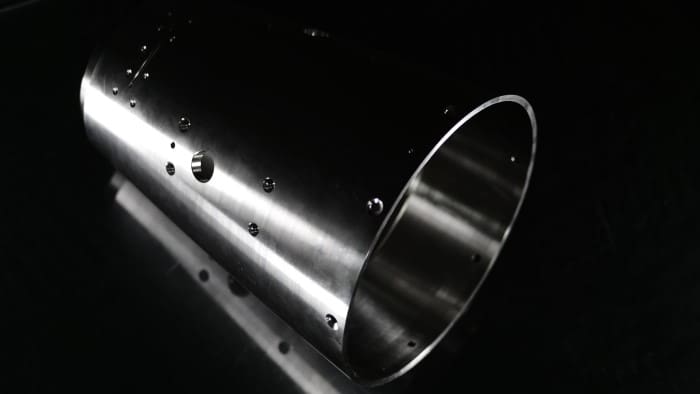

Barron Industries provides high-precision investment castings, rapid prototypes, machined components, complete assemblies, and welded fabrications for a broad range of performance-critical industries. Our custom ferrous and non-ferrous metal castings deliver quality and durability that meets the demands of even the toughest industrial applications.

For over 30 years, Barron Industries has been a key supplier and partner to leading aerospace companies which rely on Barron for technical expertise in metals, lightweighting technologies, and design for manufacturability of precision machined castings.

SERIALIZATION/TRACEABILITY.

Recognizing that lot traceability is critical to the Aerospace industry, Barron makes full use of the PLEX ERP system which provides real-time, work-in-process tracking via barcode labels. Permanent serialization is achieved with laser etching.

BROACHING / INDUCTION HARDENING / NITRO CARBORIZING / BLACK OXIDE / E COAT / A COAT / POWDER COAT / BUSHING ASSEMBLY

In addition to casting and machining, Barron Industries commonly supplies customers with complete sub-assemblies with specialty heat treating, broaching, coating, painting and part marking to our customer’s requirements.

All components are manufactured under Barron Industries AS9100 Certified quality system which includes NADCAP certification of its Non-Destructive testing services. We perform all testing, inspection, and certification in- house reducing costs and lead times by an average of 30 percent.

Barron Industries is able to meet premium mechanical properties through a combination of strict control of process and secondary thermal treatment parameters in alloys such as such as 17-4ph stainless steel and A357-T6 aluminum.

As an AS9100 manufacturer, Barron Industries produces critical aluminum precision components utilized in missiles, aircraft, and drone technologies in both domestic and foreign markets. Components produced include: the forward canard section for a 2000lb. jet launched ordinance; fuel and HVAC components on the Apache helicopter, and HVAC systems on the Boeing 767.

Speak to one of our experts today to learn more about our custom casting solutions.