Made for Strength

Carbon and Low Alloy steel castings are commonly used for pressure containing and structural applications due to the increased strength, hardenability, and resistance to wear and abrasion. Processed to obtain a wide range of properties, these alloys provide designers much flexibility and are used within many industries and applications. The relative lower cost also makes these alloys attractive for use where applicable.

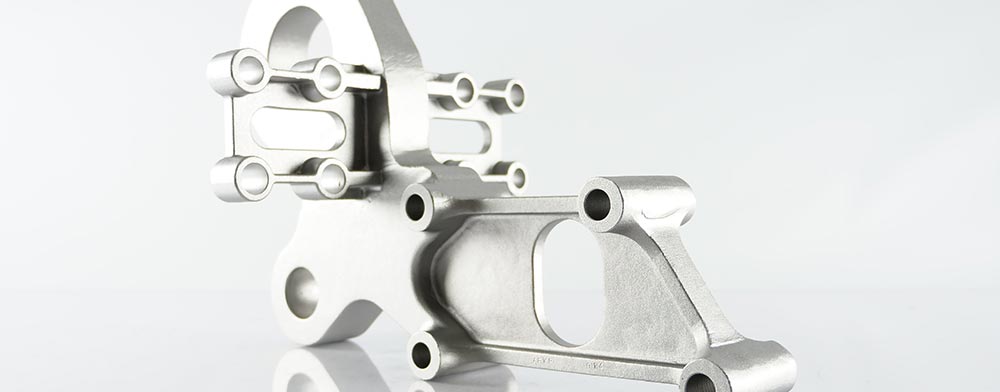

The key to economical use of the investment casting process is to fully utilize its flexibility and dimensional capability by incorporating as much added value into the casting as possible, thus eliminating or minimizing welding or machining to provide a part of high integrity and tighter tolerances.

For example, traditionally machined features such as holes and slots are cast to size and machine quality surface finish of 125 micro inches is standard for the investment casting process.

Carbon Steel

The most common metal used to manufacture products, carbon steel is also known as plain steel because it is mainly carbon with no minimum percentage of other alloying elements. Increased carbon content makes the steel harder and stronger through applications of heat treatments, but it also makes it less ductile and lowers the melting point of the alloy.

Of all investment castings manufactured at Barron Industries’ investment casting foundry, approximately 30% are made of carbon steel. These precision machined castings are used in ground-based military vehicles, “roughneck” equipment for oil and gas exploration, and conveyorized material handling systems.

Low-Alloy Steel

Alloy steels are divided into low-alloy steels and high-alloy steels, with low-alloy steels most commonly used for industrial applications. Steel is deemed to be low-ally when the amount of added alloying material comprises less than 8 percent of the metal’s total weight. The additional elements are added to increase hardness and durability. Commonly added elements in low-alloy steel investment castings are chromium, vanadium, nickel and molybdenum. The percent composition of these various alloying elements is based on the intended use of the investment casting. Low-alloy steels gain strength through heat treatment. Barron’s low-alloy steel investment castings are also resistant to corrosion and tougher than normal carbon steel. Common uses for alloy steel investment castings include agricultural equipment, defense applications and performance-critical equipment for the oil and gas industry.

OUR SPECIALTY: UNIQUE NEEDS

In the metal casting foundry business since 1923, Barron Industries melts and pours both ferrous and non-ferrous materials. In addition to aluminum, alloy steels and stainless steel, Barron pours all alloys that can be air melted or inert atmosphere melted including 600 series Inconel alloys as well as Hastelloy X and C.

Have any Questions?

Please feel free to contact us. We will get back to you within 1-2 business days. Or just call us now.